June 23, 2021

Hanbay explosion proof multi-turn stainless steel actuators were selected for a new oil & gas project off the coast of Brazil. Our actuators were seen as the only suitable product on the market for this specific project. Over 100 R-series multi-turn electric actuators with needle valves were ordered for precise and reliable control of oil and gas flow.

Hanbay R-Series actuators are compact yet robust and able to withstand harsh saline environments. The actuator housing as well as the valve and mounting kit are made of high-grade stainless steel for ultimate protection and resistance against harsh weather conditions. The actuators are rated to the international IECEX explosion proof standard Class I, Div.1, Groups B,C,D, Class II, Groups E,F,G.

Hanbay does the full assembly of valve to actuator to assure smooth and accurate control of the valve. For this project custom designed needle valves were shipped from the UK to Canada for mounting.

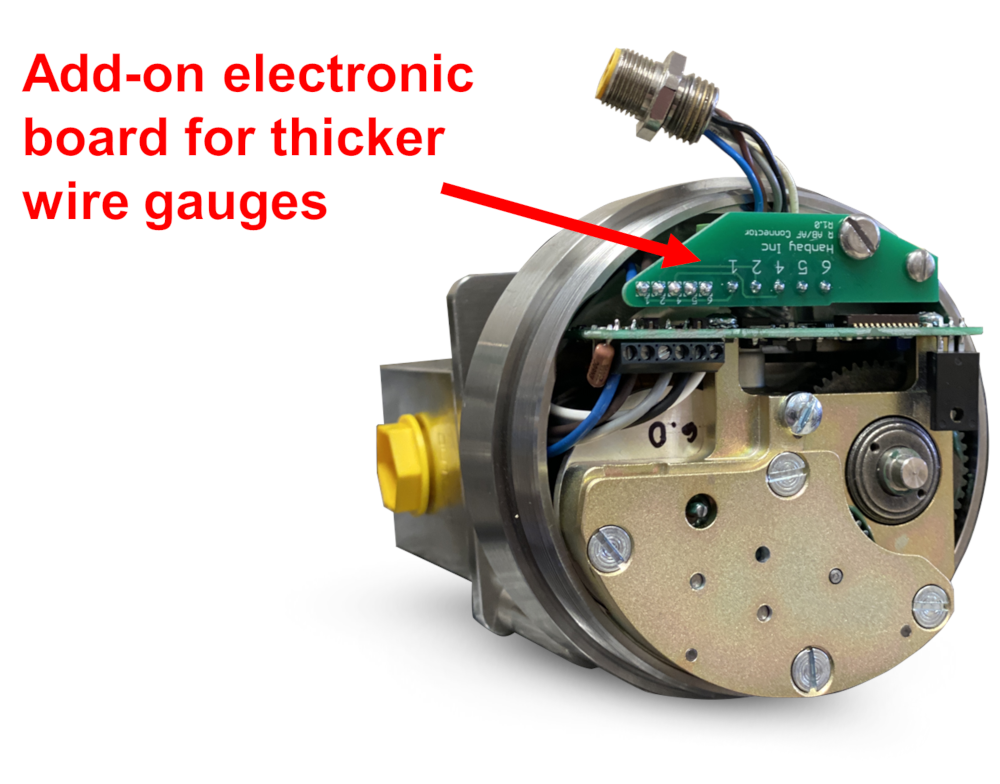

A new electronic board (Image) was developed to accommodate for thicker wire gauges specific for the project. Our usual PCB boards are made for wires of 22 gauge, with this add-on the actuators could be wired with 16 gauge wires. A small space was found inside the actuator housing to fit this additional board. The turnaround time for these custom adjustments and custom developed add-ons to our actuators can be done quickly, as Hanbay's staff works efficiently and collaboratively to come up with fast, effective solutions. This add-on feature will become available as a regular feature on our actuators in the near future. It provides a good way to adjust to different sized wires. Hanbay actuators are versatile and can adapt to any system or application.